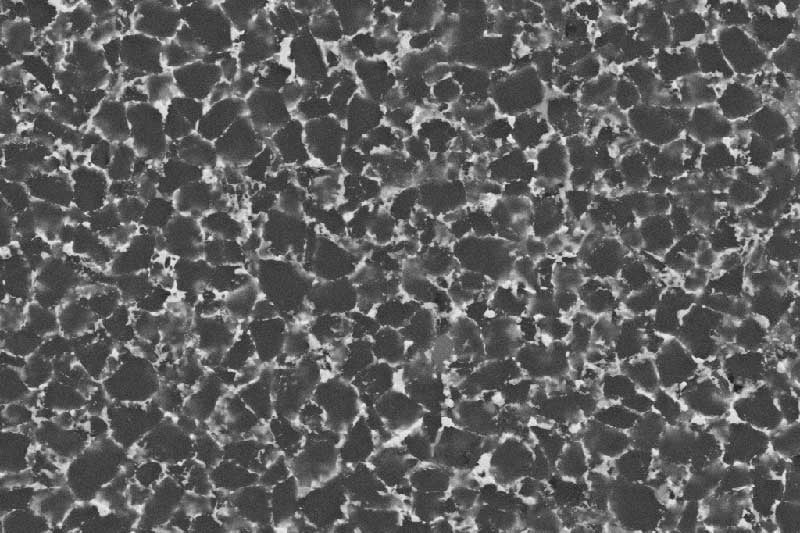

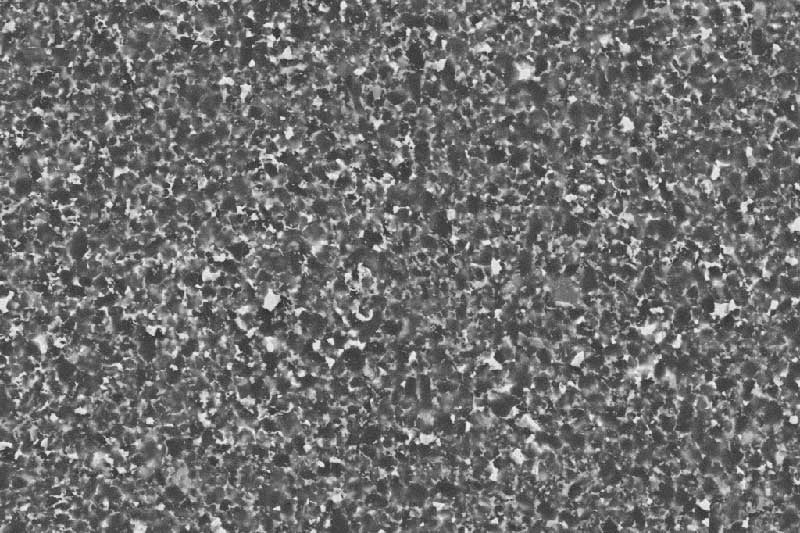

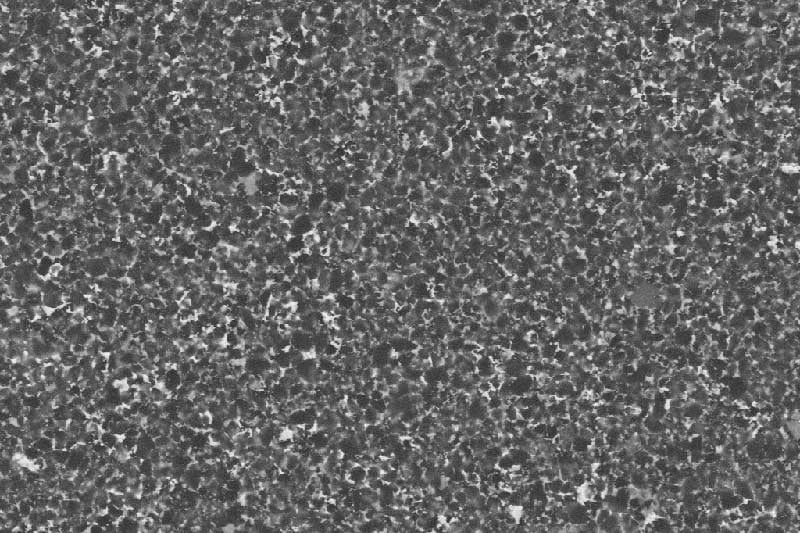

| Grade | CBN-Content [vol%] | CBN-Size [µm] | Main Binder | Application | Micro Structure |

| AN95 | 95 | 2 | Metal (Co, Al, X) |

|  |

| ATN10 | 95 | 3 | Metal (Co, Al) |  |  |

| ATN10N | 95 | 3 | Metal (Co, Al, X) |  |  |

| AN90 | 90 | 1 | Metal (Co, Al, X) |  |  |

| ATN16 | 90 | 1 | Metal (Co, Al) |  |  |

| AN65 | 65 | 1 | Ceramic (TiN) |  |  |

| AN55 | 55 | 1 | Ceramic (TiCN) |  |  |

| AN45 | 45 | 1 | Ceramic (TiCN) |  |  |

The range of workpiece materials that Adico PCBN can successfully machine is constantly ex-panding, but the main material groups are: | |

1. Hardened steels 2. Hard facing alloys 3. Chilled cast iron 4. Pearlitic grey cast irons | 5. Sintered iron 6. Superalloys e.g. Inconel 718 7. Powder metal e.g. automotive valve seats |

ADICO PCBN Products | Successful machining applications have been established in the automotive, aerospace, and manufacturing industries, and some examples are: |

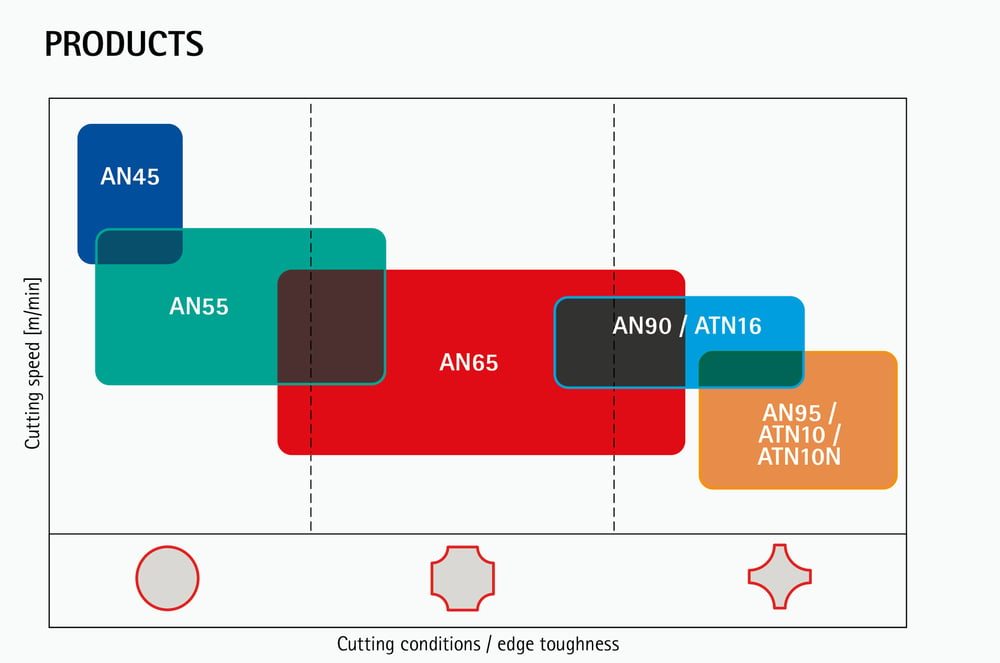

High CBN-content PCBN | |

AN95, ATN10, ATN10N |

|

AN90, ATN16 |

|

Low CBN-content PCBN | |

AN65 | moderate to heavy interrupted hard turning, finish hard milling |

AN55 | continuous & slight interrupted turning of hardened steels |

AN45 | high speed finish turning on hardened steels |

| ATN-series (Single PCBN-layer) | ADN-series (Double PCBN-layer) | ASN-series (Solid PCBN-layer) |

|  |  |

| Blank Sizes: Blank thickness (mm): 1.6, 2.0, 2.4, 3.2, 4.8 ± 0.05 PCBN thickness (mm): 0.75 ± 0.15 | Available on request | Available on request |