3. New PCD/PCBN

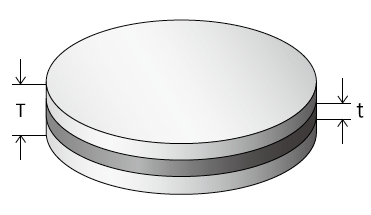

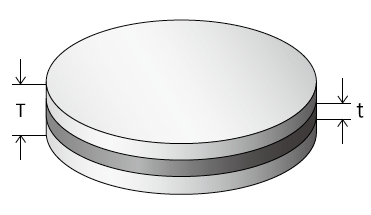

3-1) Sandwich PCD

초경 재료 사이에 PCD가 끼어있는 형태로, 주로 drill 소재로 사용됨

T : Blank thickness

t : Diamond layer thickness

PCD Grade : “FS”, “MS”, “CS”

Physical Dimension : (Half-moon of blank diameter : 62㎜)

| Blank thickness(T) | Diamond layer thickness(t) |

| 1.5mm ±0.05 | 0.5mm ±0.10 |

| 2.0mm ±0.05 | 0.8mm ±0.10 |

| 2.5mm ±0.05 | 1.0mm ±0.10 |

Product Offer : Blank Type (62Ø half-moon) Wire EDM Cut Type (  ,

,  per customer’s spec)

per customer’s spec)

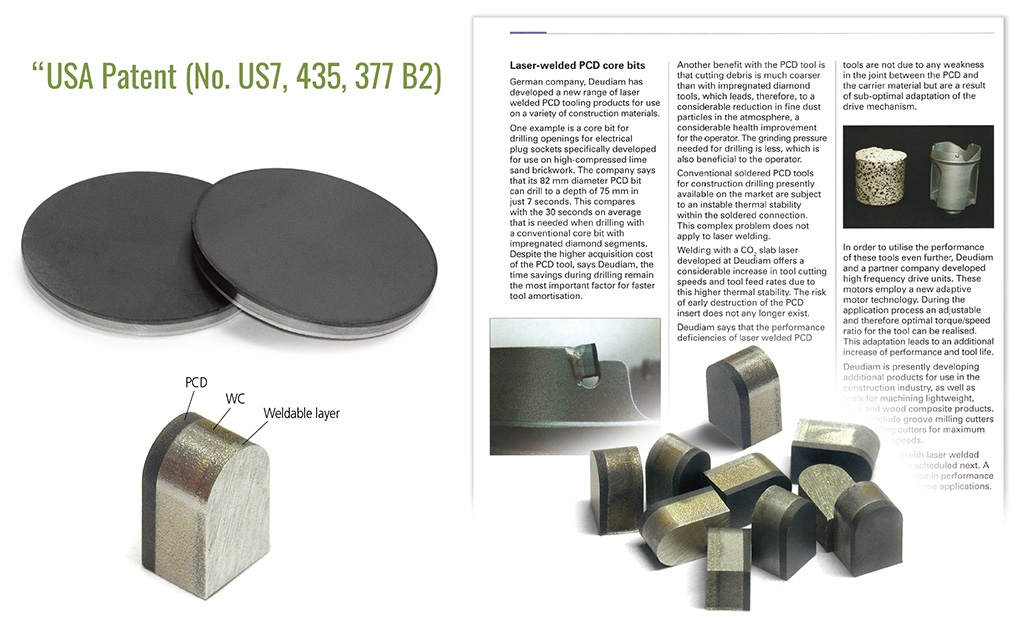

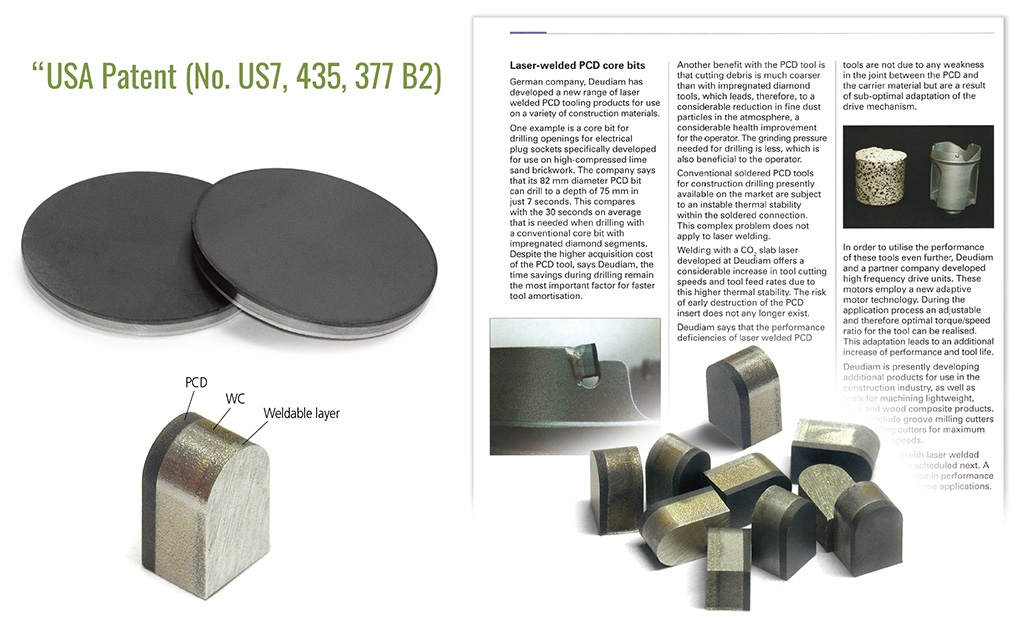

3-2) Laser Weldable PCD

PCD blade 제작시 laser 용접장비를 사용할수 있도록 기존의 PCD 소재 초경부위에 laser 용접이 가능한 금속층을 접합 합성함

Product Offer :

- Cut-pieces (wire EDM cut)

Benefit

- Exceptionally high bond strength at the welding joint between PCD and tool body.

- No risk of tool failure from unstable thermal stability related preblems.

- Cost effectiveness from no brazing.

- Offers both less health hazardous and cleaner environmental operation.

Application for Laser Welded PCD Tools

- Saw blades for cutting tiles, rocks, cement boards.

- Saw blades for road grooving cement and asphalt.

- Core bits for drilling rocks, bricks, ceramics, etc.

- Others (like conventional PCD tools)

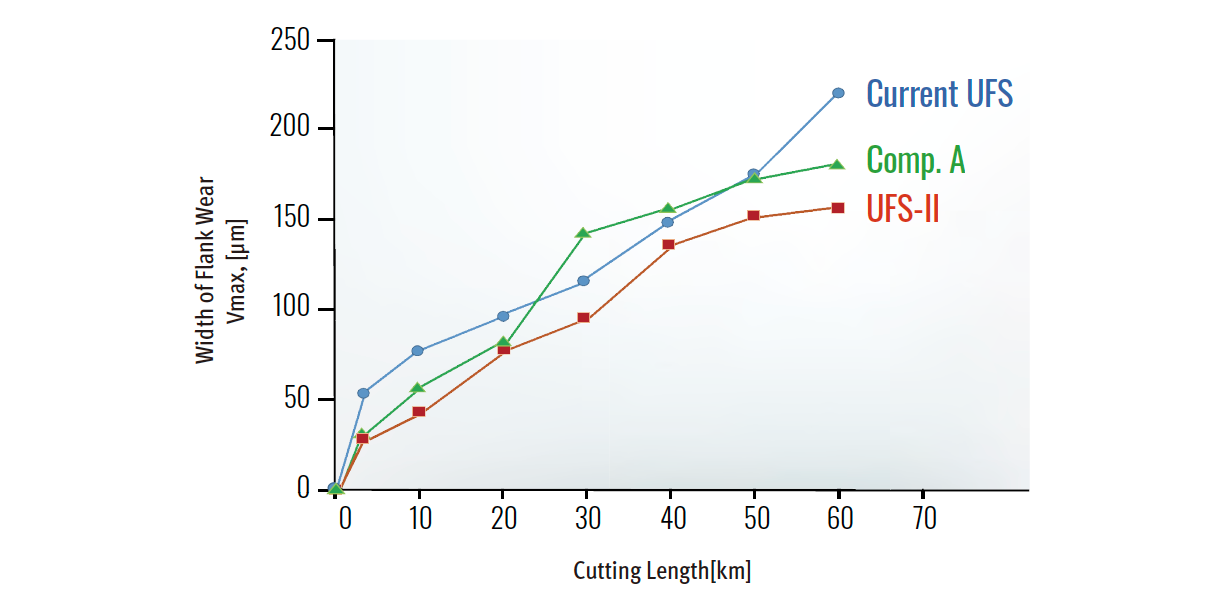

3-3) New Sub-micron PCD(UFS-Ⅱ)

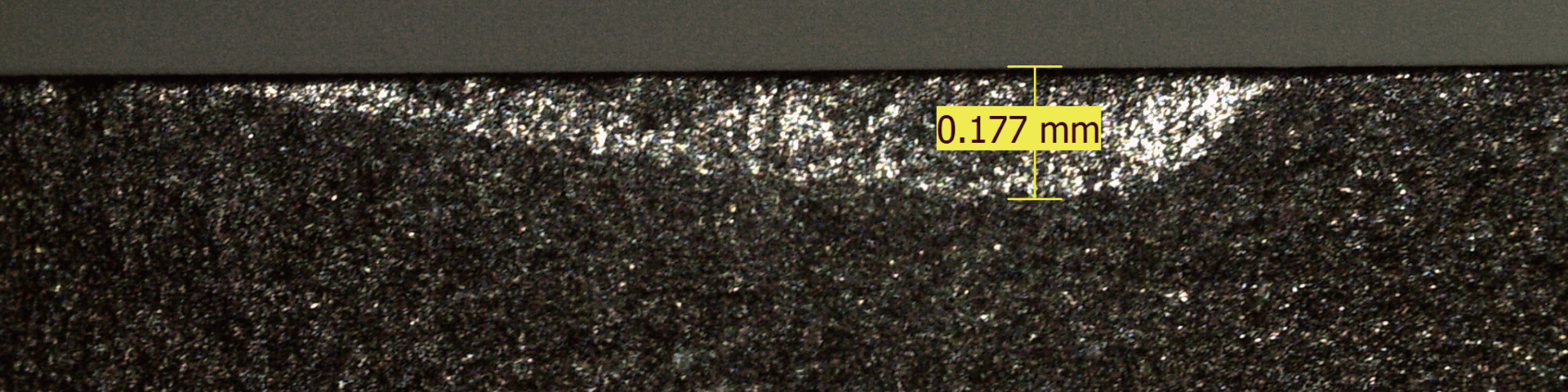

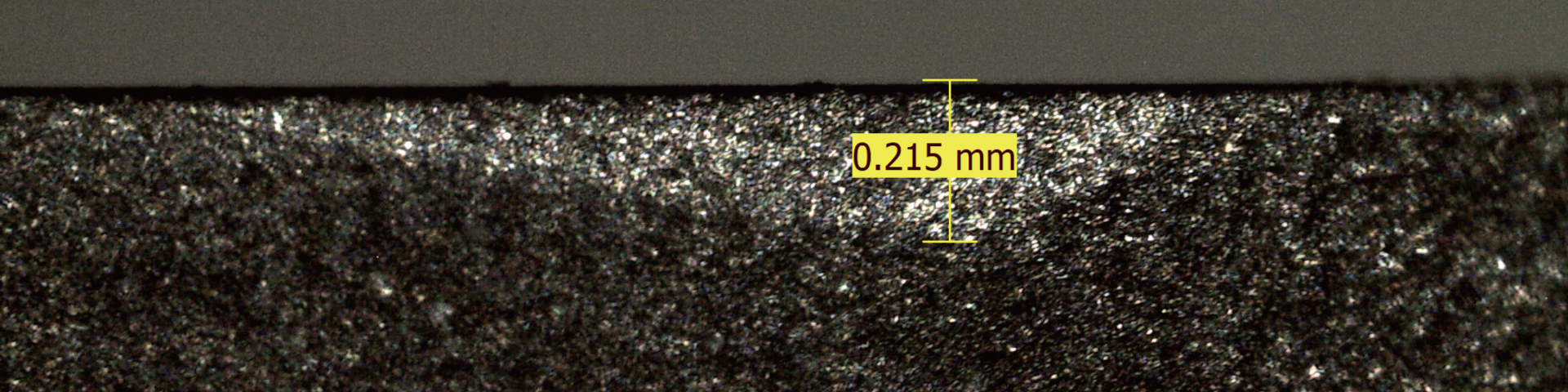

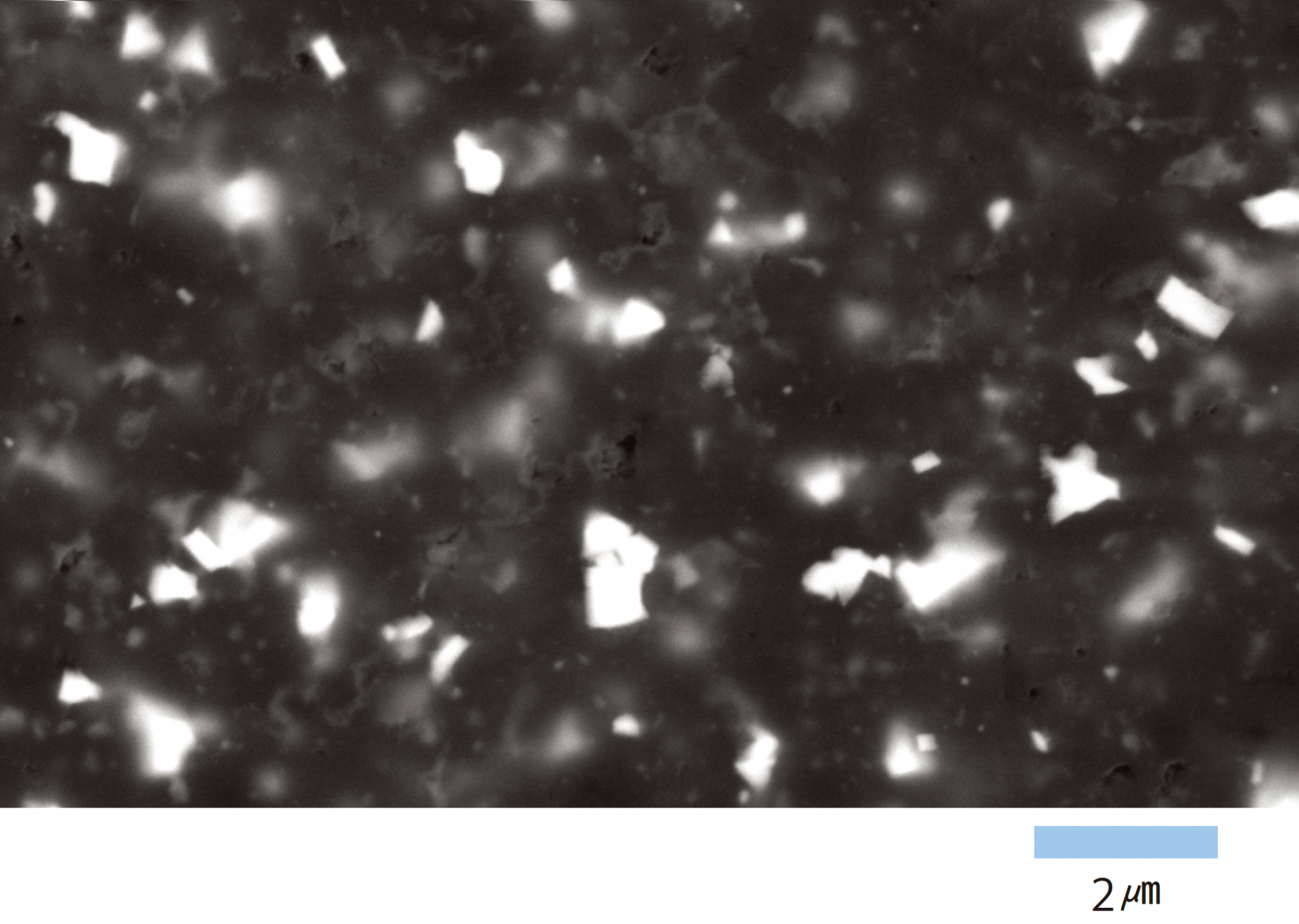

최근 ADICO 에서는 다이아몬드 입자 크기가 1micron 이하의 고순도 Ultra Fine diamond 원료를 사용하여 새로운 UFS-Ⅱ grade 개발에 성공하였다. 특히, 새로운 UFS-Ⅱ grade는 합금 분말의 혼합·믹싱 공정 개선과 독자 기술로 제작한 분산장치 개발을 통해 균질한 다이아몬드 입자 분포를 가지면서 미세조직이 보다 치밀하게 합성된 다이아몬드 소결체이다.

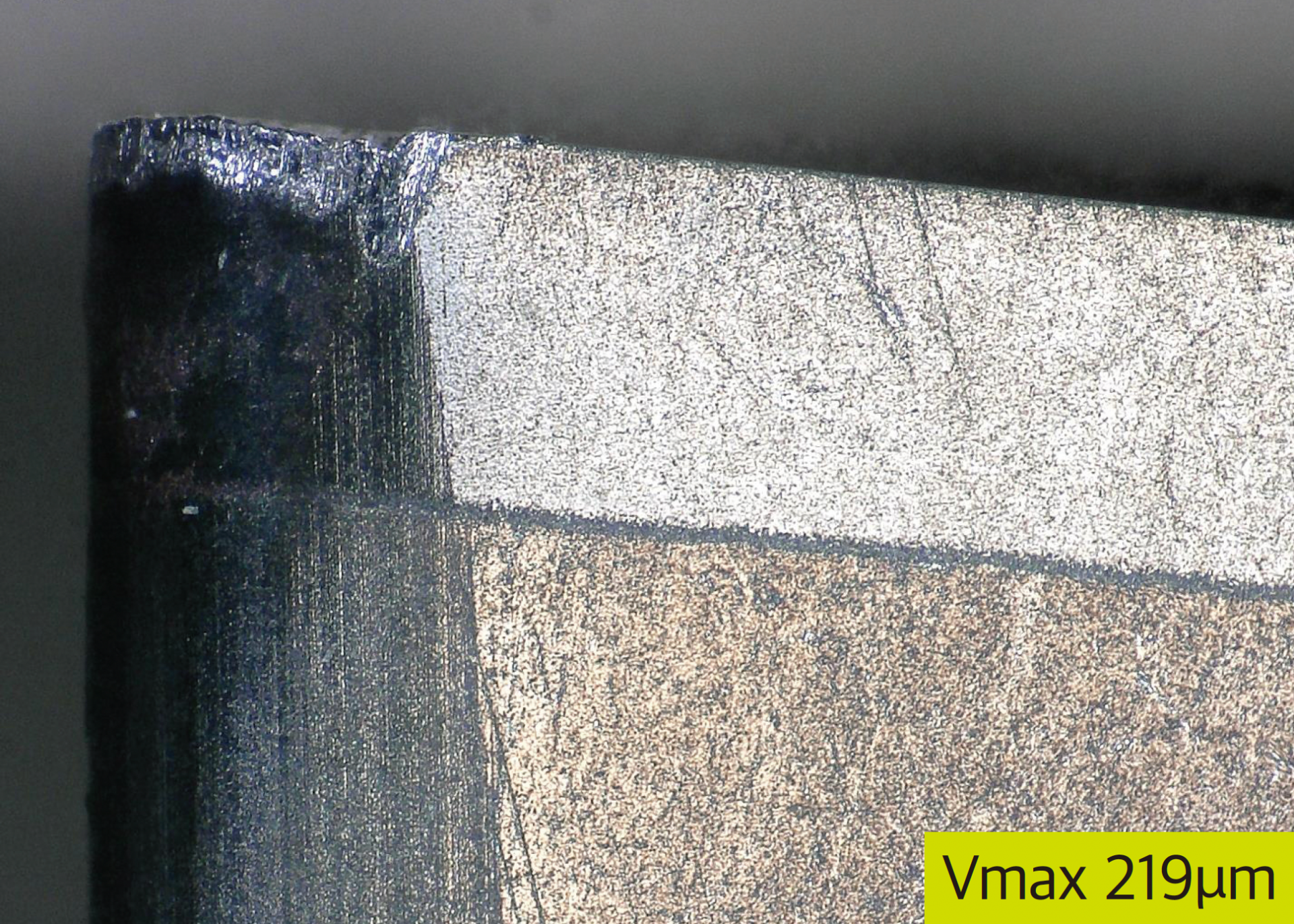

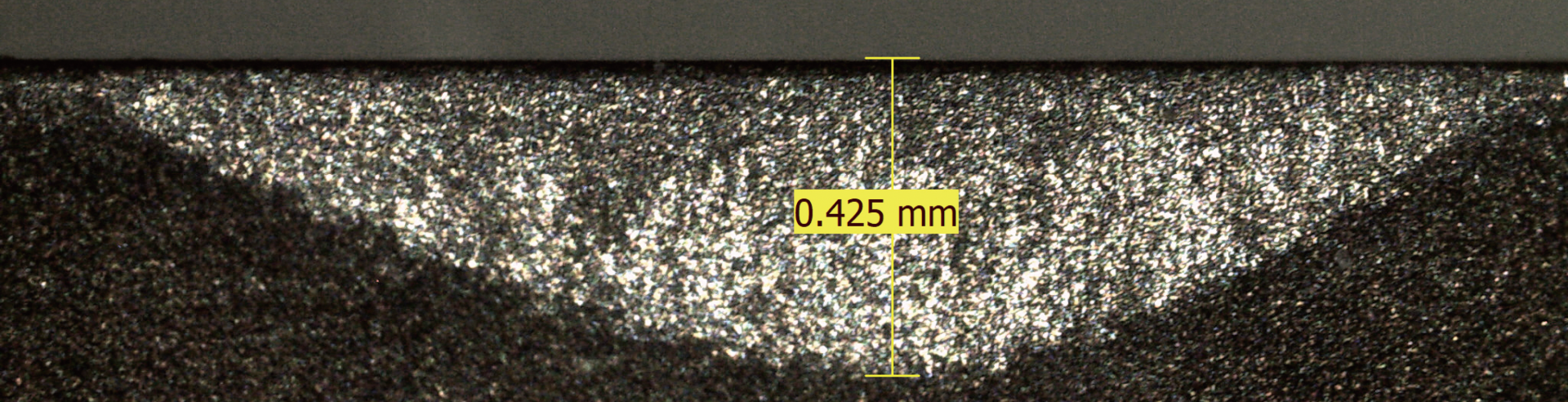

◈ UFS-Ⅱ Microstructure

공구 적용분야 : 새롭게 개발된 UFS-Ⅱ 재종은 고강도·고내마모성 다이아몬드 소결체로써, 내마모성, 내충격성 및 열전도성이 뛰어나, aluminum alloys와 Ti alloys 재료등의 선삭 공구용으로 개발되었으며, 밀링 공구 및 엔드밀로 대표되는 절삭공구에 적합하다.

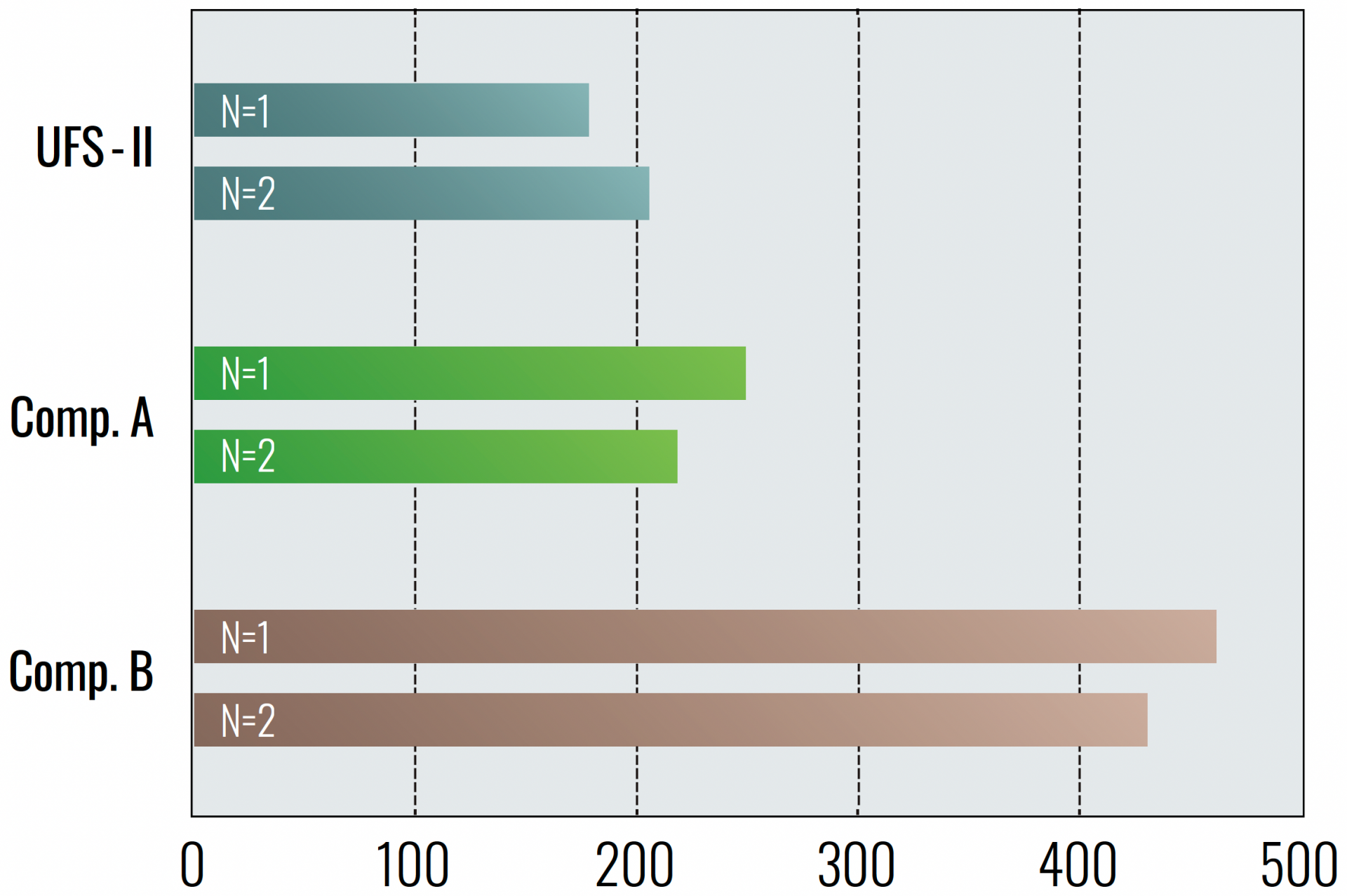

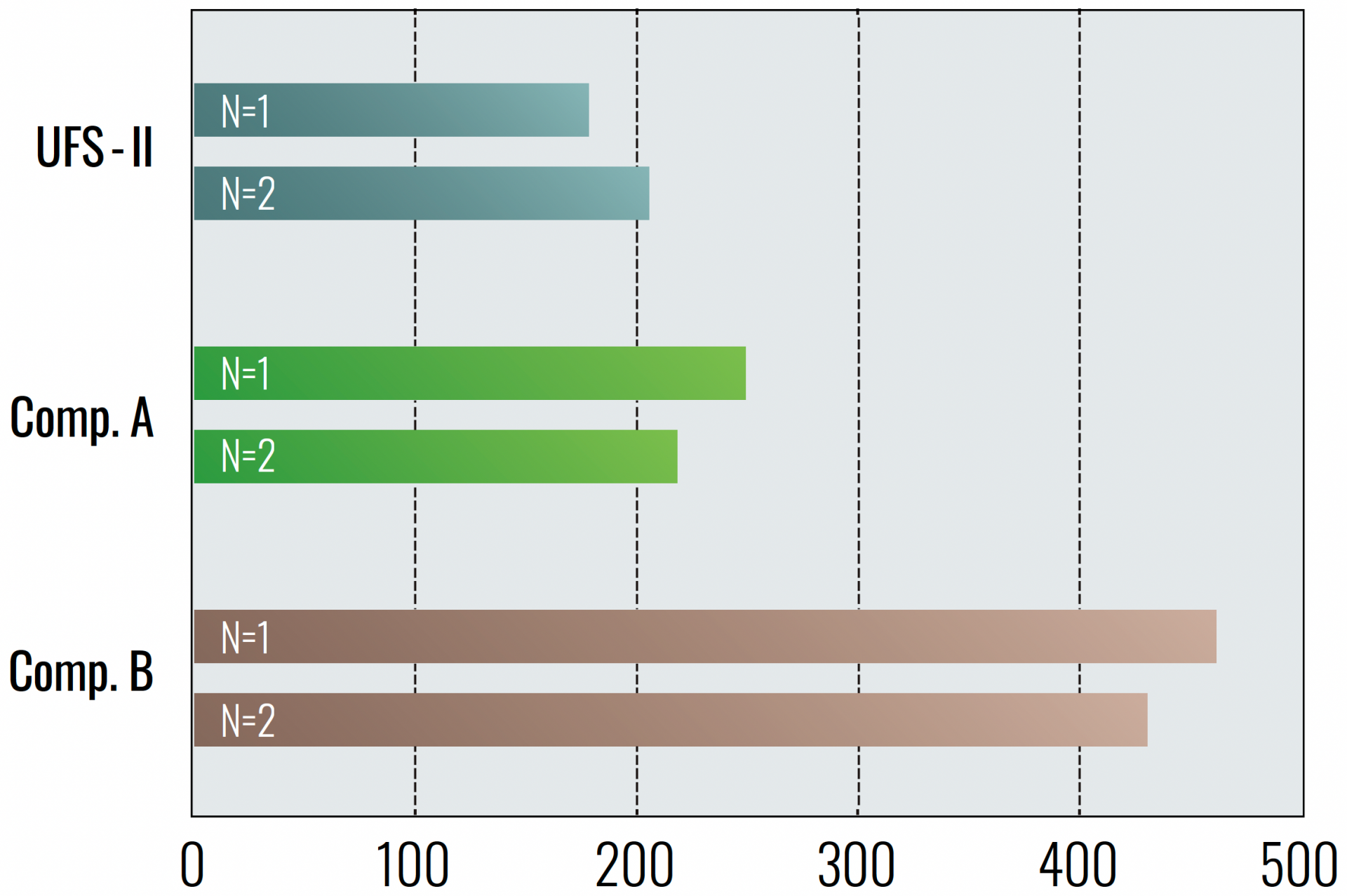

◈ UFS-Ⅱ Wear resistance test result (1)

|  UFS- II (1.5km) |

Comp. A (1.5km) |

Comp. B (1.5km) |

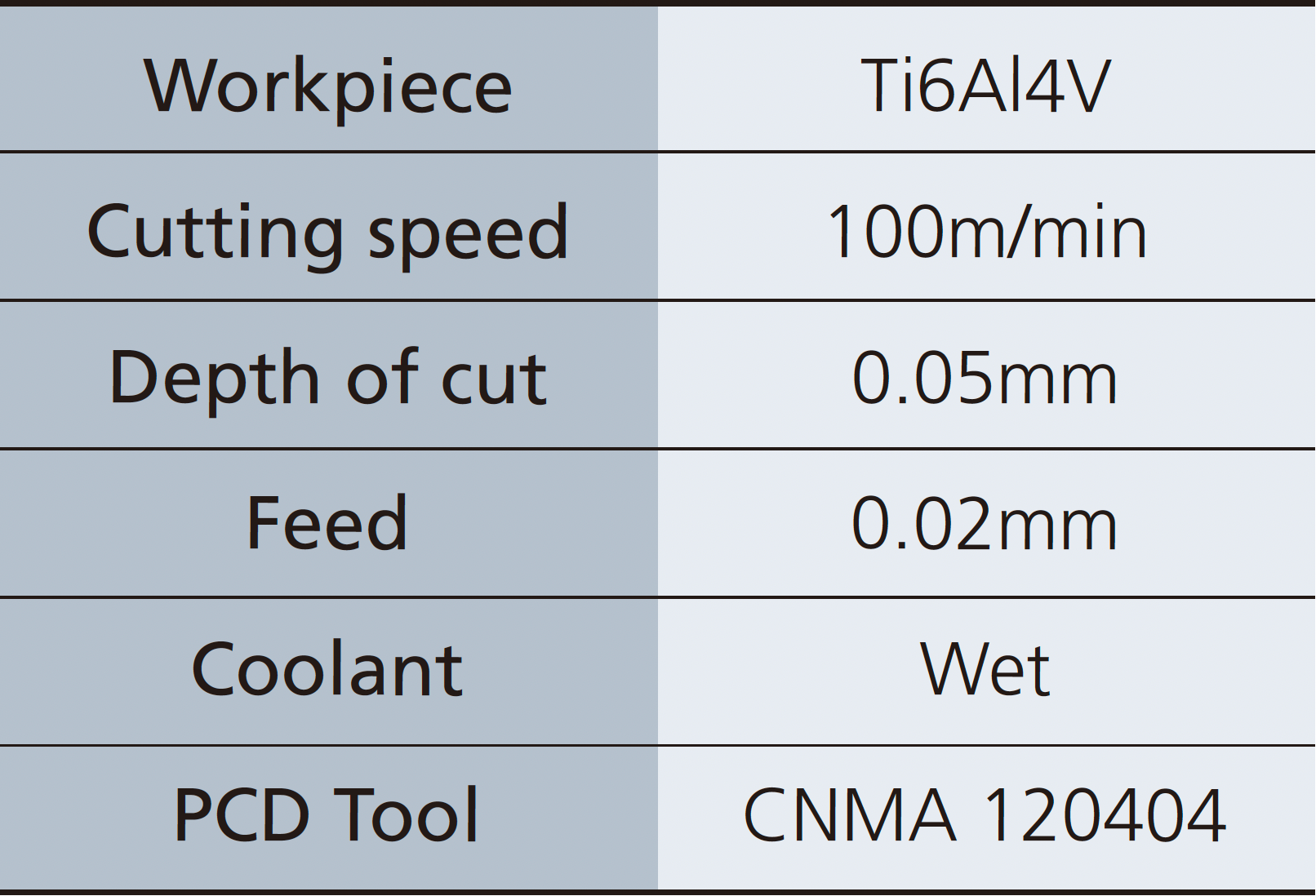

Workpiece | Cutting speed | Depth of cut | Feed | Coolant | PCD Tool |

Ceramic-based abrasive stone | 250 m/min | 0.1mm | 0.1mm | DRY | ø12.7°3.2t (Round tool shape) |

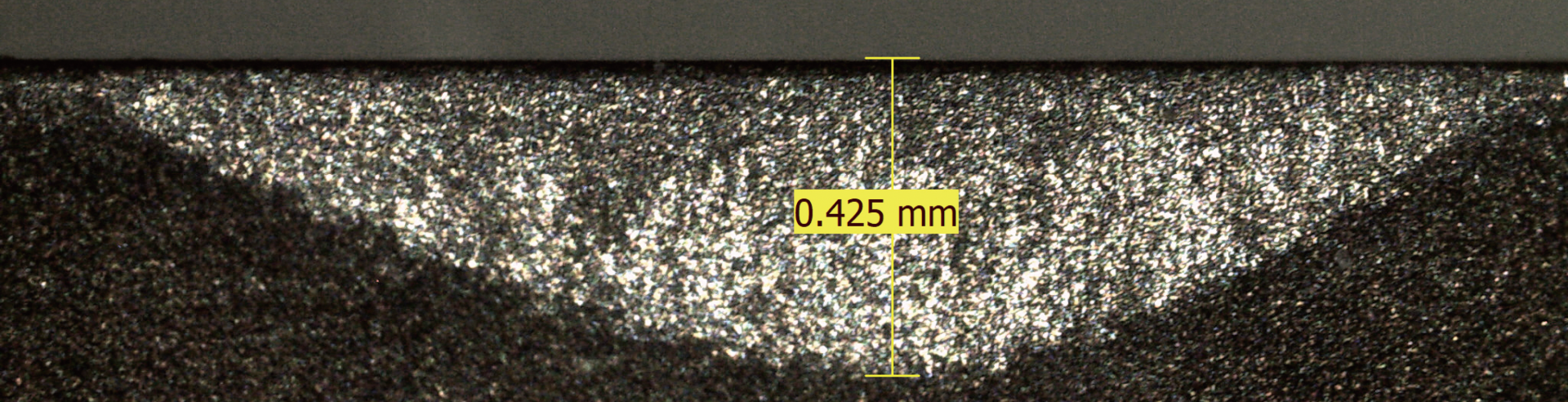

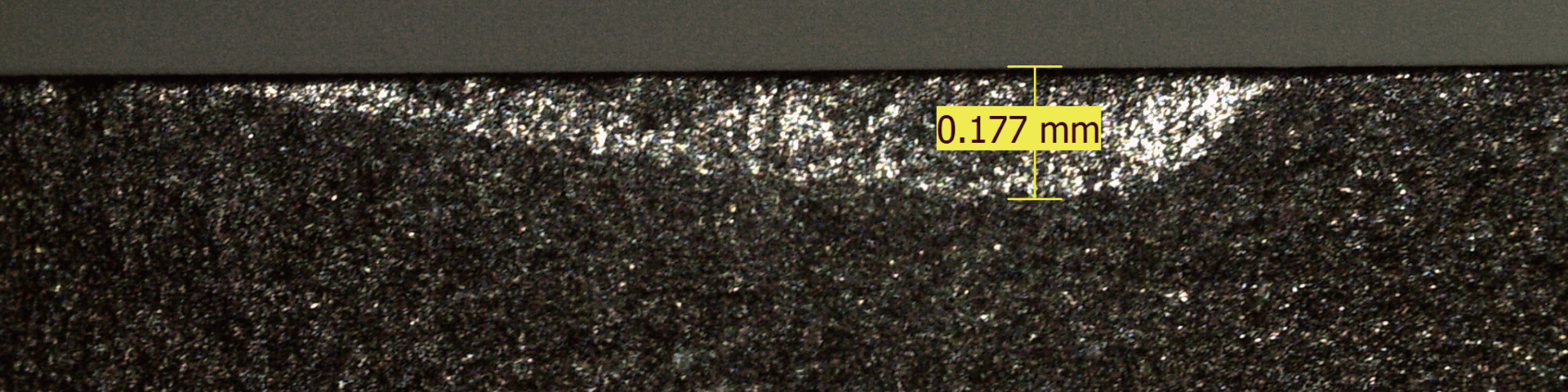

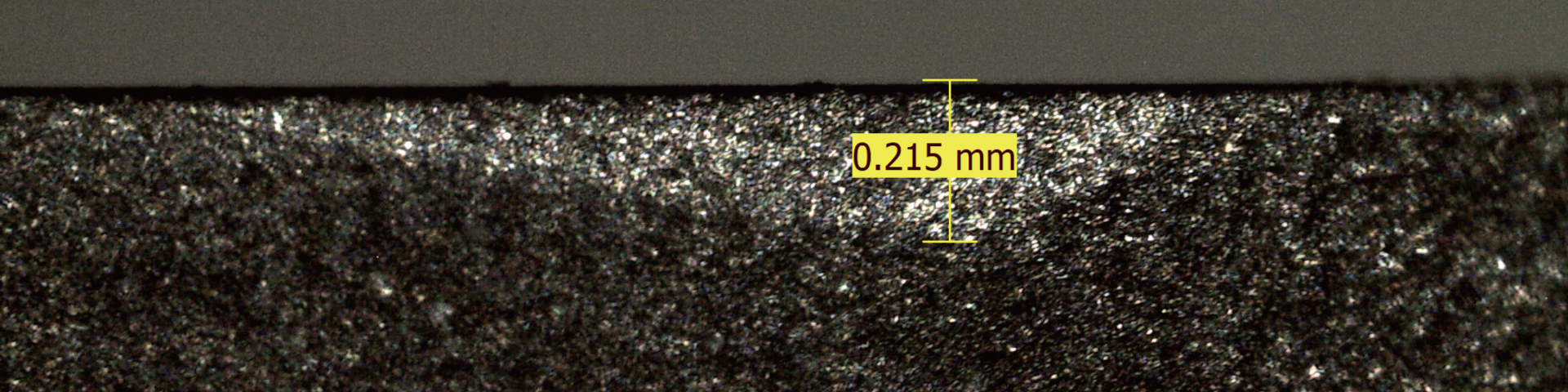

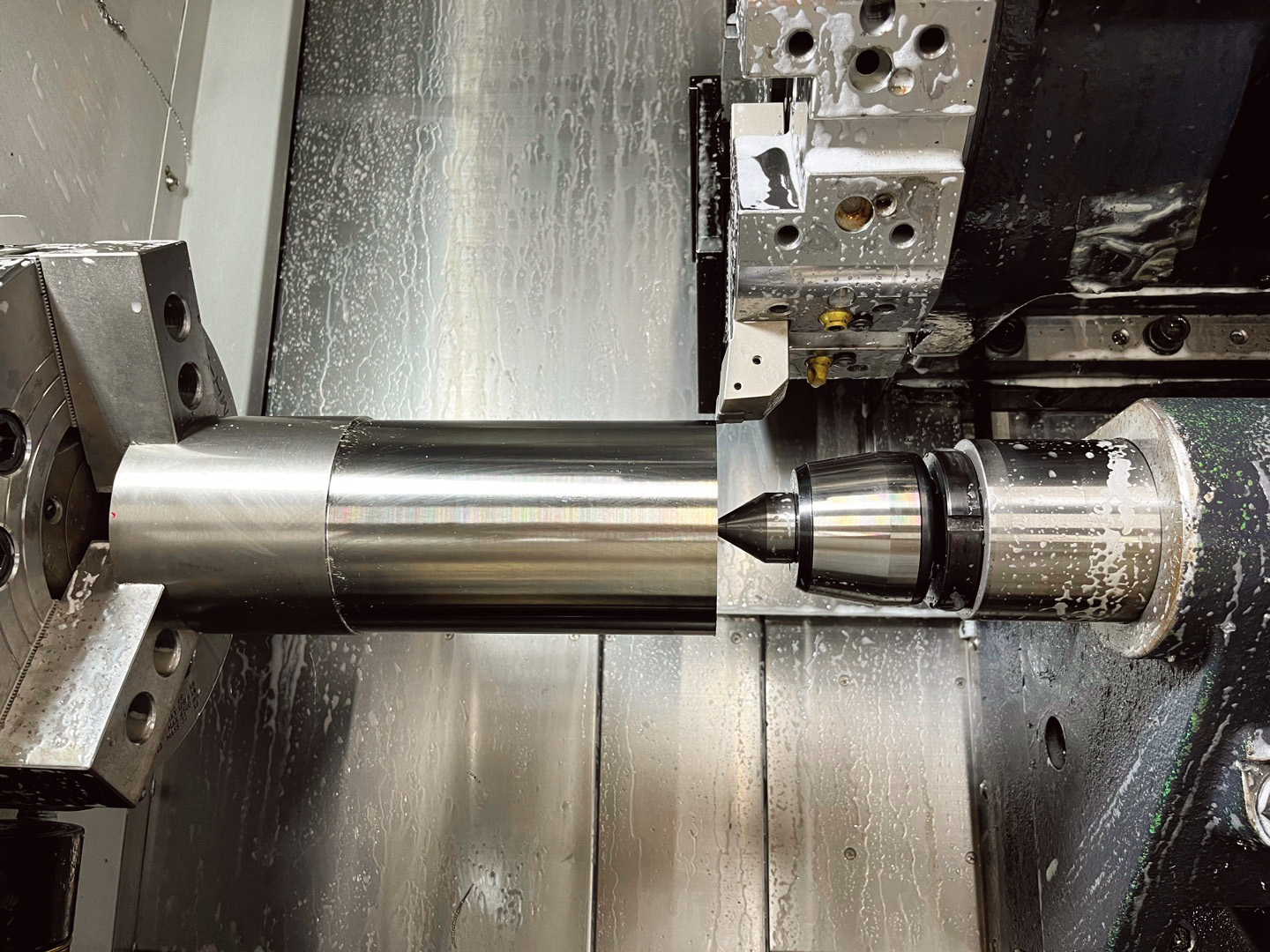

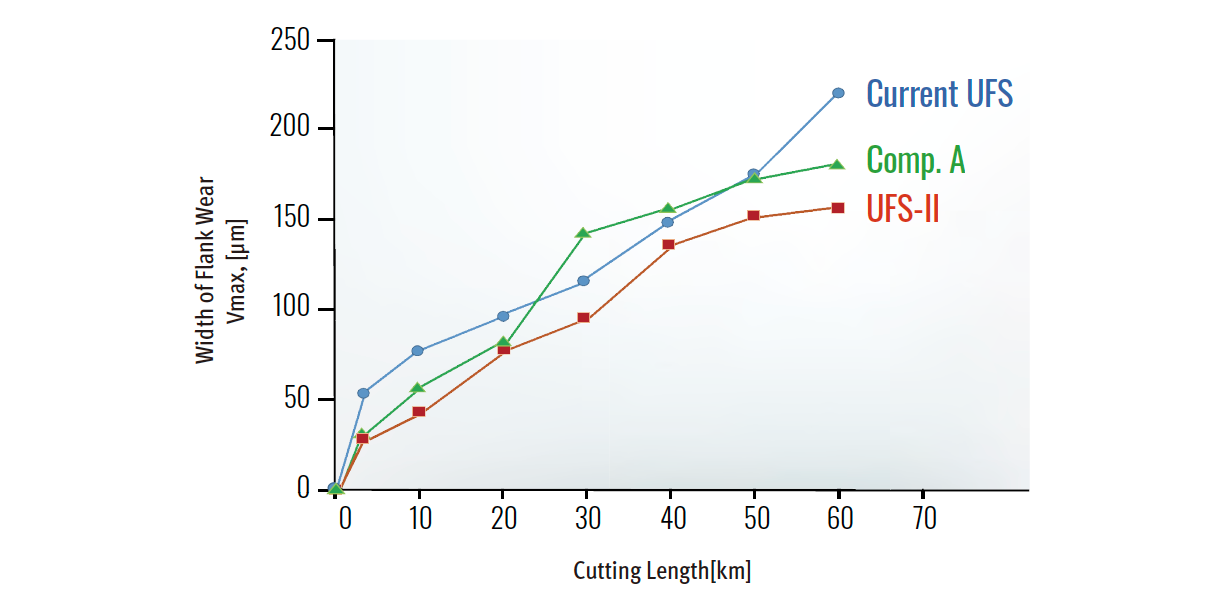

티타늄 합금(Ti6Al4V)은 우수한 강도 대 중량비와 우수한 내식성으로 인해 항공 우주 및 생물 의학 산업에서 광범위하게사용되고 있는 소재이다. 새롭게 개발된 UFS-Ⅱ는 100 m/min 절삭 속도에서 피삭재 접착으로 인한 빌트-업 에지 builtup edge)로 인한 공구 성능 저하는 나타나지 않았다.

◈ UFS-Ⅱ Wear resistance test result (2)

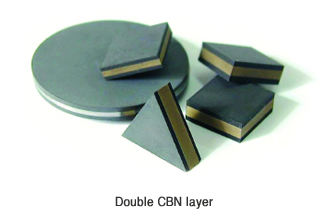

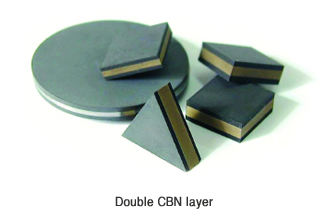

3-4) Double-sided PCBN

PCBN 소재 사이에 초경 재료가 끼어있는 형태로, 기존의 Solid PCBN에 비하여 고품질, 고강성, tool 제작시 양호한 용접성을 제공

,

,  per customer’s spec)

per customer’s spec)

UFS- II (1.5km)

UFS- II (1.5km) Comp. A (1.5km)

Comp. A (1.5km) Comp. B (1.5km)

Comp. B (1.5km)

Comp. A

Comp. A